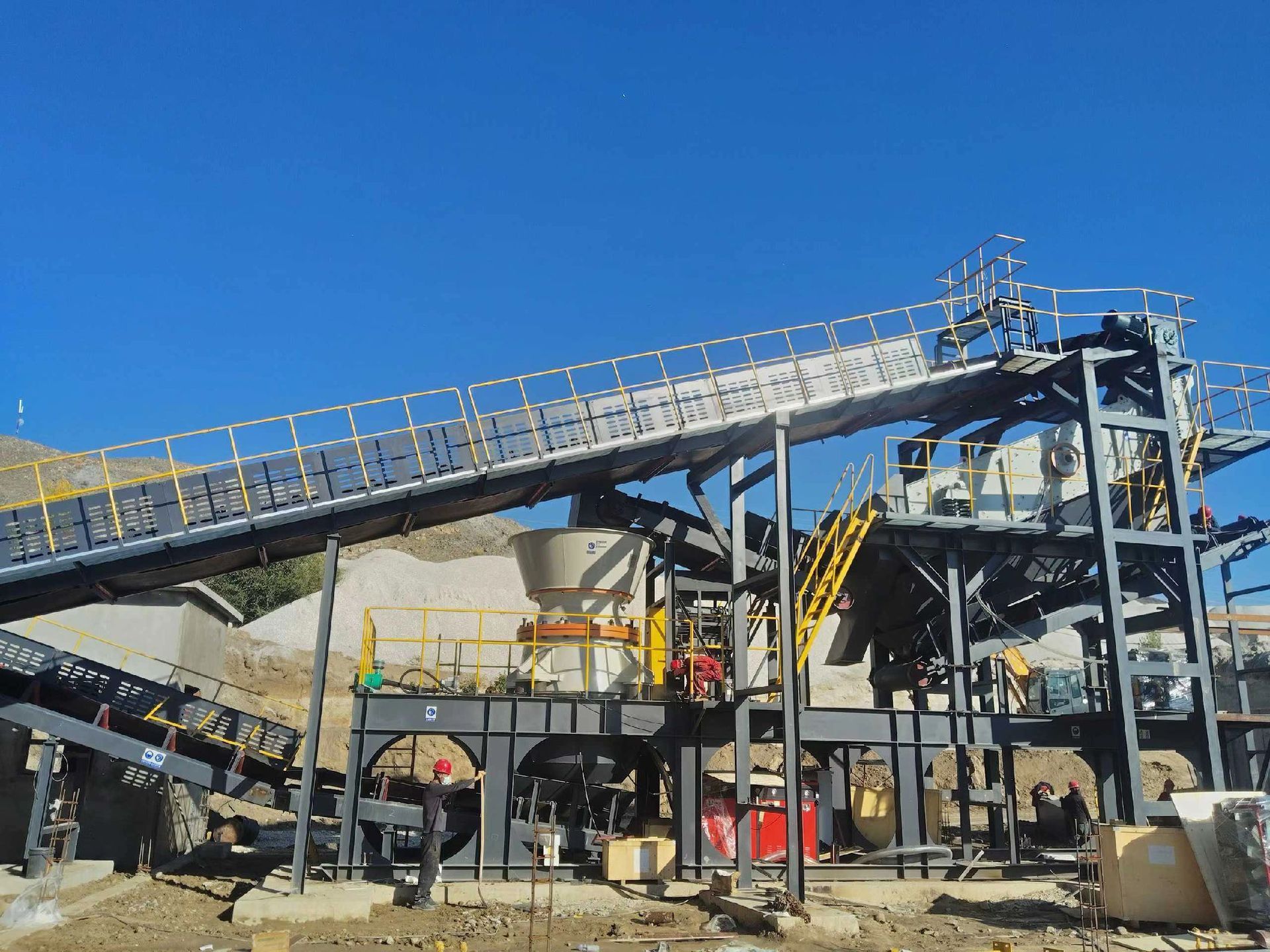

Our Service

We specialize in the design and manufacture of AAC (Aerated Concrete) block/Panels production lines, as well as mining stone crushing and sand-making equipment and calcining rotary kiln production equipment. We offer a variety of aerated concrete block forming machines, sand and gravel aggregate production lines, mining stone crushing production lines, sand-making production lines, energy-saving lime rotary kilns, cement rotary kilns, building ceramic aggregate rotary kilns, and solid waste and hazardous waste rotary kilns. Henan Ruichi, with its expertise, has become a trusted partner in the industry.

We provide turnkey projects, providing comprehensive support throughout the entire process, ensuring a worry-free partnership. We provide precise pre-sales matching, efficient implementation, and long-term after-sales maintenance.