Henan Ruichi 150,000 Cubic Meter Annual AAC Autoclaved Aerated Concrete (AAC) Panel Production Line Commences Operation in Kyrgyzstan

Recently, Henan Ruichi held a grand commissioning ceremony for its AAC autoclaved aerated concrete (AAC) panel production line in Kyrgyzstan. As a key project in the local green building materials industry, this 150,000 cubic meter annual AAC production line, fully installed and delivered by Ruichi's AAC factory, marks Kyrgyzstan's construction industry's entry into the era of localized production of high-performance AAC autoclaved concrete products. The project encompasses comprehensive services from equipment customization to after-sales training, not only meeting the growing demand for high-quality, durable building materials from the local construction industry but also showcasing the strong capabilities of Chinese AAC block machine manufacturers in overseas key project projects.

Superior Equipment Performance: Laying a Solid Foundation for Stable and Efficient Production

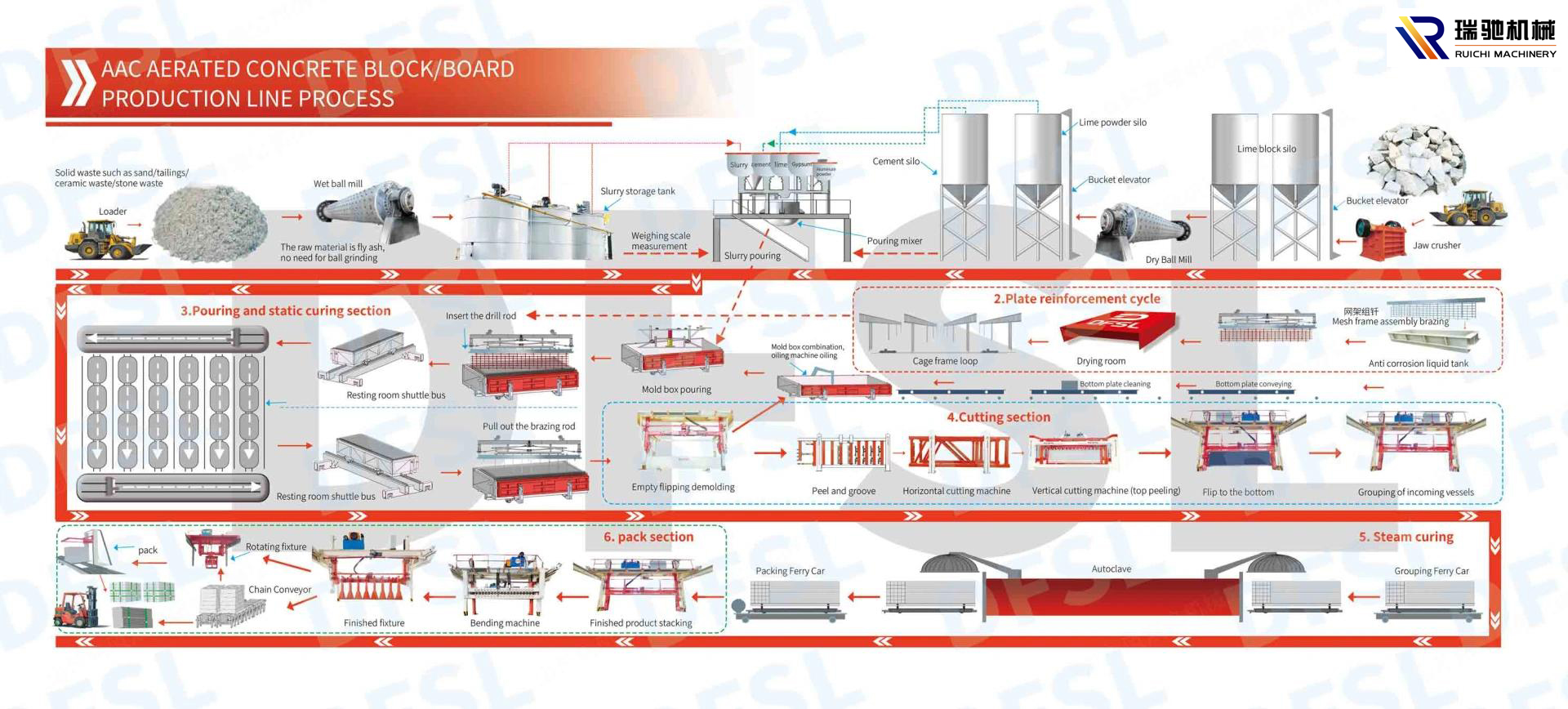

The newly commissioned AAC block and panel production line is equipped with core independently developed equipment from Henan Ruichi, integrating advanced structural design and mature production technology. The entire production line consists of high-performance key equipment, including heavy-duty slurry tanks, high-efficiency casting mixers, precision cutting units, and large-capacity autoclaves. Each piece of equipment boasts superior performance advantages and is custom-designed to meet the industrial environment and construction needs of Kyrgyzstan.

The heavy-duty slurry tanks feature a double-layer insulation structure, effectively solving the problem of slurry solidification caused by low temperatures in the mountainous regions of Kyrgyzstan. The tank body is constructed of high-quality corrosion-resistant steel, extending its service life by 30% compared to ordinary tanks. An internal high-speed mixing device ensures uniform mixing of raw materials, preventing sedimentation and stratification. The high-efficiency casting mixer employs a special spiral mixing blade structure, increasing mixing efficiency by 25% while maintaining slurry fineness. The casting system utilizes servo-driven quantitative casting technology, achieving a casting accuracy error within ±2%, fundamentally guaranteeing the consistency of product billet density and strength.

The precision cutting unit is equipped with high-hardness alloy cutting wires and a stable gantry frame structure. Employing in-frame oscillating cutting technology, it enables precise cutting of plates and blocks on the same production line. The cutting accuracy error is less than 1mm, fully meeting the stringent dimensional accuracy requirements for aerated concrete (AAC) panels and blocks. The large-capacity autoclave, a core piece of equipment in the production line, features an optimized internal pressure distribution design, operating at 1.3MPa with a stable temperature control within ±5℃. A steam circulation system ensures uniform heating and curing, reducing curing time to 6-8 hours while simultaneously improving the product's compressive strength and durability.

Furthermore, the entire production line adopts a modular design, facilitating on-site installation and commissioning while reducing subsequent maintenance difficulties. Addressing the power supply characteristics of Kyrgyzstan, the equipment is equipped with a voltage stabilization system to prevent production interruptions caused by voltage fluctuations. Henan Ruichi also optimized the equipment's sealing performance to suit the dry and windy climate, effectively preventing dust from entering the equipment and affecting its service life.

As the general contractor, Henan Ruichi completed the entire process from factory layout design and equipment installation and commissioning to personnel training within 150 days, fully demonstrating the professional capabilities of an AAC plant manufacturer in overseas key-operation projects. The project manager in Kyrgyzstan stated, “The performance of the Ruichi autoclaved aerated concrete (AAC) block molding machine is stable, adaptable, and highly efficient, exceeding our expectations. This production line can fully meet the local market's demand for high-quality AAC products and will effectively advance our localization process for green building materials.”

Diversified Product Portfolio: Fully Meeting Local Construction Needs

A major highlight of this AAC autoclaved aerated concrete (AAC) panel production line is its powerful product portfolio, capable of simultaneously producing two core products: AAC panels and AAC blocks, perfectly matching the personalized needs of the Kyrgyz construction market. With the continued development of Kyrgyzstan's construction industry, particularly the booming development of housing, transportation and logistics, and urban infrastructure projects, the demand for high-performance, multi-specification building materials is increasing.

Among them, the company produces AAC panels with a maximum length of 6 meters. This large-size specification is particularly suitable for large-scale buildings, such as local commercial complexes, industrial plants, and public facilities, significantly reducing the number of joints during construction and improving construction efficiency. Autoclaved aerated concrete (AAC) blocks can be customized according to internationally accepted specifications, including standard sizes such as 600mm×200mm×240mm and 600mm×200mm×100mm, fully meeting the construction needs of residential buildings, public facilities, and small and medium-sized industrial plants.

It is worth mentioning that all products from this production line fully comply with Chinese building standards and have been approved by the Kyrgyz government. This not only ensures product quality but also facilitates the promotion and application of products in key local projects. The diversified product range not only enhances the market competitiveness of the AAC block factory but also provides local builders with more high-quality choices, helping to address the pain points of limited building material variety and high import costs in Kyrgyzstan.

Superior Product Performance: Adaptable to Local Environment and Construction Needs

The AAC products produced by this production line possess excellent comprehensive performance, highly aligned with Kyrgyzstan's policy direction of developing green and energy-efficient buildings and the need for earthquake-resistant construction. The product features lightweight construction (density as low as 500 kg/m³), high strength (compressive strength ≥ 3.5 MPa), excellent thermal insulation (thermal conductivity ≤ 0.12 W/(m·K)), and superior sound insulation. Given Kyrgyzstan's cold winters and large diurnal temperature variations, the product's excellent thermal insulation effectively reduces building heating energy consumption, aligning with the local government's strategy of prioritizing renewable energy and energy conservation.

Furthermore, the production process utilizes local siliceous materials (such as sand and tailings) recycling technology, which not only reduces the cost of aerated concrete blocks but also complies with Kyrgyzstan's environmental protection policies, such as the Environmental Protection Law and the Vegetation Utilization and Protection Law. The project has also been included in Kyrgyzstan's list of priority industrial enterprises, enjoying tax incentives such as income tax and value-added tax reductions, further enhancing its profitability and market competitiveness.

In terms of application scenarios, the product is widely used in wall construction, interior and exterior wall insulation, floor slabs, and roof panels in various types of buildings. Kyrgyzstan, located in an earthquake-prone region, utilizes specially formulated aerated concrete block adhesives to construct walls with excellent seismic resistance, effectively enhancing building safety. Six-meter-long aerated concrete panels can be directly used for partition wall construction in high-rise residential and public buildings, significantly improving construction efficiency and shortening the construction period. Furthermore, this product boasts excellent fire resistance, with a fire resistance limit exceeding 4 hours, meeting the fire protection requirements of various building types.

Henan Ruichi's Strong Strength: Supporting Overseas Projects with Professional Services

The successful commissioning of the Kyrgyzstan project is inseparable from the strong comprehensive strength of Henan Ruichi, a leading manufacturer of aerated concrete block machinery. For many years, Ruichi has been committed to the research, development, production, and sales of aerated concrete production line equipment, possessing mature technical experience in autoclaved aerated concrete (AAC) production lines and AAC panel production lines. The company has a professional R&D team capable of customizing equipment solutions based on the climate, resources, and policy characteristics of different countries and regions.