60-200 tons per hour sand production line

The sand production line equipment can be used for aggregates and artificial sand making operations of various materials such as hard limestone, granite, basalt, river pebbles, and smelting slag. It is suitable for applications in hydropower, building materials, highways, urban construction and other industries. Our factory can combine various types of equipment according to different process requirements to meet the different process requirements of customers.

Basalt has the advantages of strong compressive resistance, low crushing value, strong corrosion resistance, and good asphalt adhesion. It is internationally recognized as a better material for the construction of roads, railways, and airport runways. Not only that, basalt is also a high-quality aggregate for lightweight concrete in high-rise buildings. Due to its porous and hard characteristics, mixing it into concrete can reduce the weight of concrete without losing its strength. It also has the advantages of sound insulation and heat insulation, and is deeply favored by major building materials markets. The demand for basalt raw materials is very strong, and the investment prospects of basalt are bright.

Process flow

The granite (basalt) sand production line with an output of 60-200 tons per hour will load the large pieces of raw materials less than 425mm after blasting or excavation and mining into the raw material bin through a dump truck, and evenly supply them to the jaw crusher for crushing through a grizzly feeder with a pre-screening function. The semi-finished products after crushing by the jaw crusher are about 50-120mm in size, and are transported to the cone crusher with a medium and fine crushing function through a belt conveyor for secondary crushing. The mixed finished aggregates after secondary crushing by the cone crusher are transported to the subsequent first screening workshop through a belt conveyor for grading and screening. The large particles larger than the user's needs are returned to the cone crusher for cyclic crushing through a belt conveyor, and the qualified finished products that meet the customer's needs are transported to the finished product bin through a belt conveyor. If the finished sand needs to be washed, a sand washer can be configured under the first screen for washing the finished sand. The grizzly feeder of this system also has a pre-screening function, which can separate the fine particles in the raw materials in advance and directly enter the subsequent crushing equipment, and can also separate the soil and debris in the raw materials as discarded materials in advance.

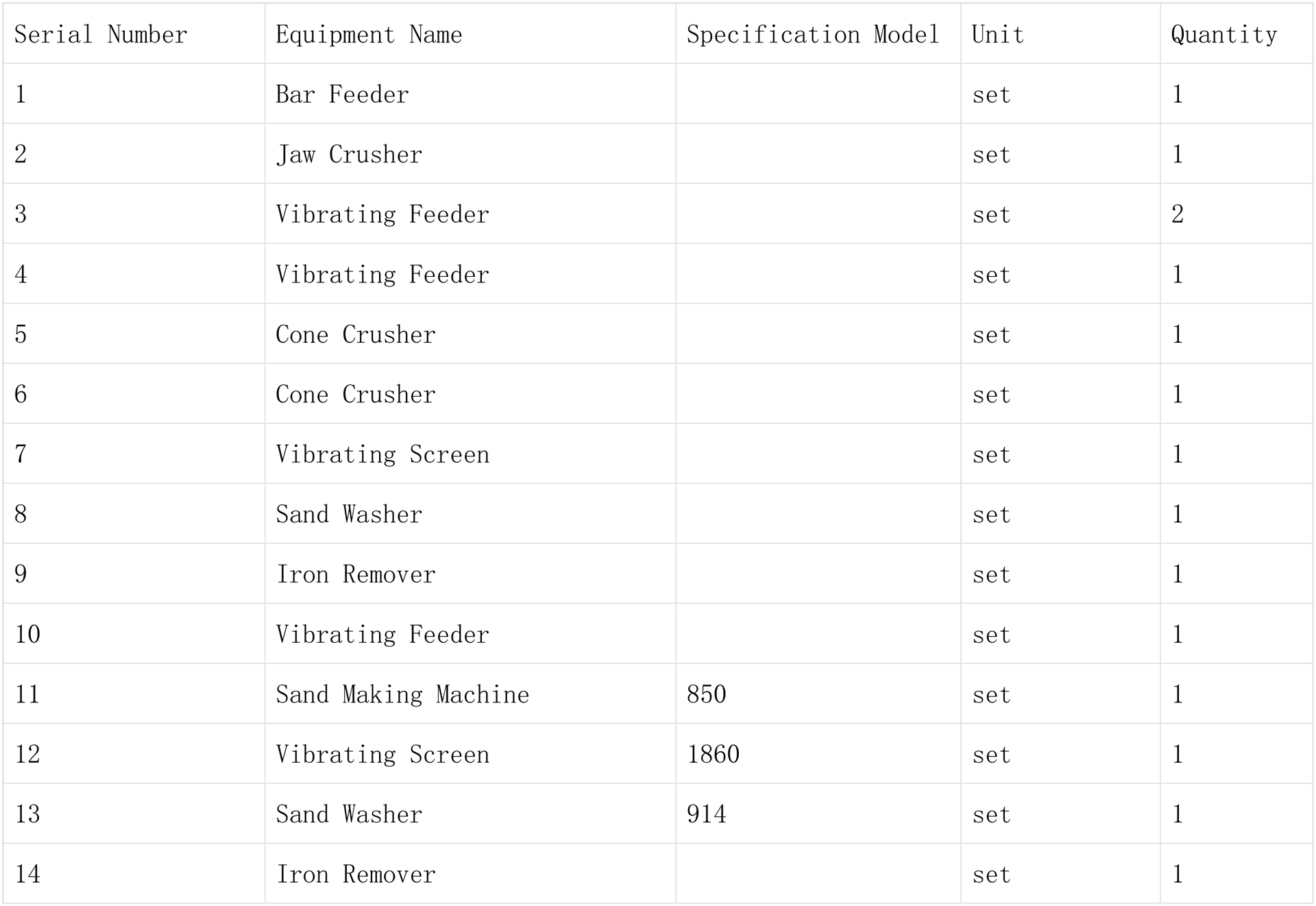

Equipment configuration for 60-200 tons per hour: